As the building reinforcement standards continue to increase, more and more reinforcement methods are applied to different building reinforcements, such as the common planting bar reinforcement technology, carbon fiber reinforcement technology, and bonding steel technology.

Today, we will introduce you to a very common reinforcement technology—outside-wrapped steel reinforcement technology. Outside-wrapped steel reinforcement is a widely used method for reinforcing concrete members. It is usually wrapped with steel or steel plate on the surface of the original component, four corners or both sides. And injecting the steel glue between the surface of the concrete member and the gap of the outer steel, and using the lateral splicing plate or the ferrule as the connecting member to improve the overall mechanical performance of the reinforced member. Outer steel reinforcement technology can usually be divided into wet method and dry method. What is the difference between wet and dry? And listen to our explanation one by one:

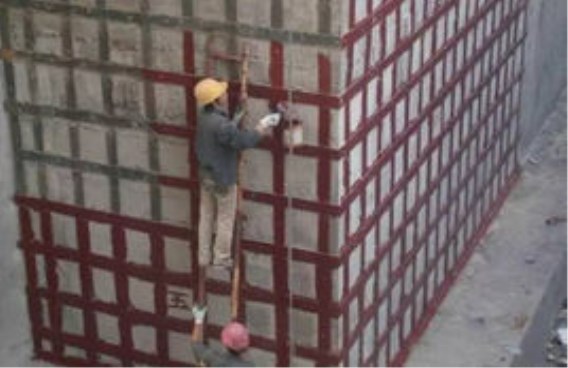

Outsourcing steel construction site picture

What is wet (dry) outsourcing steel reinforcement technology?

The outer steel reinforcement method is divided into dry and wet. The wet-outer steel method is filled with steel-filled adhesive between the steel and the original component, so that the new and old materials have better working ability, and the overall performance is good, but the wet work is large. And for the dry-out steel method, there is no bond between the steel and the original component. Sometimes it is filled with cement mortar, but it does not ensure the effective transmission of the joint shear force and tensile force. The steel and the original component cannot work as a whole, and they can only be subjected to force alone.

What is the difference between wet-wrapped steel reinforcement technology and dry-type wet-out steel reinforcement technology?

Compared with wet-out steel, dry-outer steel construction is simpler, but the bearing capacity is not as effective as wet-outer steel. The method can greatly improve the bearing capacity of the member and increase the ductility and rigidity without substantially changing the cross-sectional dimensions of the original structural members, and is suitable for the reinforcement of structural members and structures such as concrete columns, beams, roof trusses and brick window walls, and chimneys. The outer steel reinforcement method is particularly suitable for the reinforcement of the axial center and the eccentric compression member which are not allowed to increase the sectional size and which need to greatly increase the bearing capacity.

Outsourcing steel reinforcement effect diagram

For more information about wet-outer steel reinforcement and dry-out steel reinforcement, please feel free to contact Mankate. Mankate is at your service. Your needs are our pursuit~

Link to this article: https://www.njmkt.net/Article/sswbgjgfhg.html

(Editor: Nanjing Mankate, if you need to reprint, please indicate the source)