Building carbon fiber reinforcement technology is a commonly used method in building reinforcement engineering. Compared with traditional bonded steel reinforcement method and enlarged section method, building carbon fiber reinforcement technology has many advantages such as convenient operation, low material cost and short construction period. Therefore, it has become the object of choice for more and more people. Safety is the foundation of construction engineering. How can building carbon fiber reinforcement technology with many advantages improve structural safety during construction? Let’s uncover this answer for everyone:

(Effects after reinforcement of bridge carbon fiber cloth)

In general, the building carbon fiber reinforcement project is mainly to improve the safety performance of the structure from the aspects of construction preparation, concrete surface treatment, carbon fiber cloth cutting, bonding resin configuration, and multi-layer bonding treatment.

1. Building carbon fiber reinforcement and construction-construction preparation

Before the construction of carbon fiber reinforcement, it is necessary to read the design drawings and construction drawings of the construction project. The specific construction site should correspond to the construction drawings and locate the reinforcement parts. The construction scheme and the specific construction plan are based on the construction drawings, and the materials and tools required for the construction are prepared in advance.

2, Building carbon fiber reinforcement and construction - concrete surface treatment Before the construction of carbon fiber reinforcement, the surface of the construction site should be cleaned to keep the surface of the concrete structure layer flat. After the concrete surface is smoothed, use a hair dryer to clean the surface dust of the concrete and keep the concrete surface dry.

3, Building carbon fiber reinforcement and construction - carbon fiber cloth cutting

The size of carbon fiber cloth cutting needs to be determined according to the area of the reinforcement part. The vertical cutting method is used for cutting, avoiding the phenomenon of drawing. The cut carbon fiber cloth should keep the surface clean and free from external dust, so as not to affect the reinforcement effect.

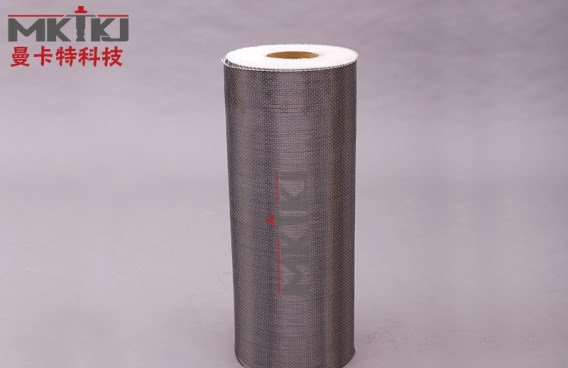

(Mankate carbon fiber cloth)

4, Building carbon fiber reinforcement and construction - carbon fiber glue configuration Carbon fiber glue configuration needs to be formulated according to the instructions and the proportion. We should eliminate waste. The specific preparation methods and requirements of carbon fiber glue produced by different brands and manufacturers are different. The construction party should prepare according to the preparation process and ratio provided by the manufacturer when preparing carbon fiber glue. The prepared carbon fiber glue is stirred clockwise, and the mixing process should be carried out in a non-polluting environment to prevent impurities, dust and the like from being mixed into the carbon fiber glue.

5, Building carbon fiber reinforcement and construction - multi-layer paste processing When doing multi-layer paste, pay attention to grasp the timeliness. The surface of carbon fiber cloth should be immediately attached to the next layer after drying. If it is more than 40 minutes, we need to wait for 12 hours, and then paste the next layer after re-smear bonding resin.

The reinforcement effects of floor carbon fiber cloth

Building carbon fiber reinforcement engineering not only requires these professional construction process knowledge, but also requires high-quality carbon fiber material support. Only when both are combined can the structural safety stability be greatly improved. Nanjing Mankate has an independent research and development team of material. And all carbon fiber cloth and carbon fiber board are made of imported carbon fiber raw materials, and we have an independent construction team and after-sales service team. We provide the whole process one-stop service for you.

Link to this article: https://www.njmkt.net/Article/txwjggczrh.html

(Editor: Nanjing Mankate, if you need to reprint, please indicate the source)