More and more curved pre-buried channels have entered the field of engineering and are known to everyone. So if we use curved pre-buried channels in our projects, how do we install them? Because there are many types of curved pre-buried channels, we take the high-speed rail tunnel as an example to explain.

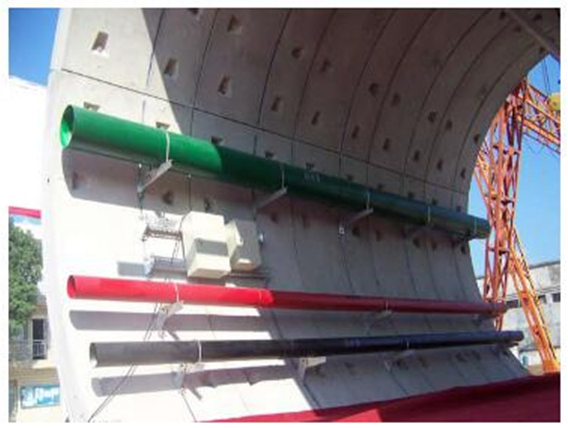

High-speed rails need to open tunnels in many mountainous terrains. The contactless embedded parts and integrated grounding system in the high-speed rail tunnel are the key to ensuring the smooth operation of the tunnel. The contact network in the high-speed railway tunnel is fixed by the high-speed tunnel pre-buried channel (referred to as the channel) and suspended from the top or wall of the tunnel. It is suitable for the contact net suspension column and additional wire suspension in the tunnel.

Generally speaking, the high-speed tunnel pre-buried channel is opened in the lining trolley according to the design requirements. The principle of drilling holes includes reducing the number of openings of the trolley template according to the length, model and length of the channel. This is very important and needs attention. First use the total station meter to measure the position of the center line, then use the steel ruler to draw the positioning reference line, measure the channel spacing and cut the T-bolt positioning hole by oxygen welding. Then use the matching T-bolt to fix it on the trolley formwork. Note that the matching bolts must be used here, otherwise it is difficult to achieve the expected effect. After the lining concrete is poured, loosen the bolts and take back the formwork.

The high-speed rail tunnel pre-buried channel is mainly composed of two parts: the slide rail and the I-type anchor. These two parts are very important because it mainly relies on the gripping force between the I-type rivet and the lining concrete to provide a contact net strut. Under the force platform, this force can play the role of fixed contact net suspension column and additional wire suspension, and will include the static load generated by the contact net and the contact column due to its own weight and the dynamic load generated by the friction between the trains. Type rivets are transmitted to the concrete. If you are interested in this product, please contact Mankate Professional Technical Consultant.

Link to this article: https://www.njmkt.net/Article/gtsdymcdrh.html

(Editor: Nanjing Mankate, if you need to reprint, please indicate the source)