When it comes to the tunnel pre-buried channel technology, it was first used in nuclear power projects. Later, it was gradually used in building curtain walls, high-speed railway tunnels, bridges, municipal tunnels, power tunnels, and rail transit. Later, it obtained successful construction operation experience in Wuhan-Guangzhou high-speed railway, Zhengzhou-Xi’an high-speed railway, Guangzhou-Shenzhen-Hong Kong high-speed railway, Hefei-Fuzhou high-speed railway and Shenzhen Metro Line 9, thus opening up a successful mode of contact network suspension scheme in high-speed railway tunnel.

What is a tunnel pre-buried channel?

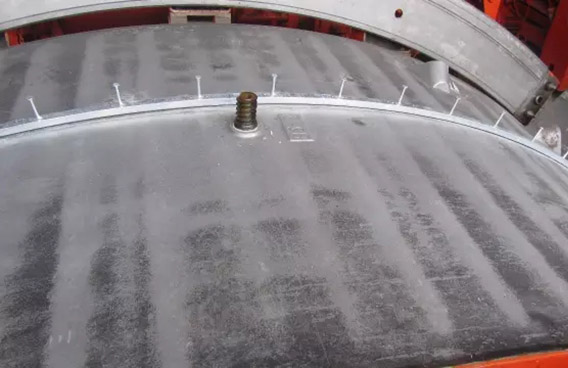

The tunnel pre-buried channel technology means that the C-shaped channel steel is pre-buried in the concrete tube piece during the pre-fabrication process of the tube piece, and the cable, pipeline, equipment, etc. are fixed on the shield tube piece by T-bolt during the later electromechanical installation, which will significantly reduce damage to the structure and save safety time.

How to pre-bury the tunnel pre-buried channel? How to install and fix it?

The tunnel pre-buried channel is a kind of pre-installed in the concealed project, which can stabilize the external project. Most of it is made of metal. In the structure, the steel plate and the anchoring rib are left in the structure. It can be used to connect structural members. This can be used as a connector for fixed use in the post-order. Generally, it is necessary to use the embedded parts first to perform related processing according to the drawings, then to perform measurement positioning and to set up brackets and the like.

Tunnel pre-buried channel construction drawing

The role of tunnel pre-buried channel

1. The pre-buried channel is conducive to forming a reinforced integral linear structure in the lining surface layer. It is not a single point of force, but a uniform force.

2. Ensure that the force and vibration of the contact net do not damage the integrity of the tunnel lining. At the same time, it can meet the strength requirements of the high-speed train wind power to install the equipment and the buried foundation in the tunnel, and also meet the fine installation standard of the high-speed contact net.

3. The tunnel pre-buried channel is closely attached to the lining trolley. After the mold is removed, it is flush with the lining surface, and the appearance is round and beautiful.

Among the past subway construction, basically the concrete was first poured, and the concrete walls and the tops on both sides of the tunnel were formed, and then the troughs, holes and bridges, pipes, and cables were installed. This not only causes great waste of manpower and material resources, but also the pipelines and lines are interlaced and intertwined, which brings great difficulties for the management and maintenance of later operations. With tunnel pre-buried channel technology, the construction efficiency can be increased by three times, and post-maintenance costs can be saved.

This article links to https://www.njmkt.net/Mobile/MArticles/sdymcdsdwt.html

(Editor: Nanjing Mankate, if you need to reprint, please indicate the source)