What is adhesive mold expanded-base anchor?

The adhesive mold expanded-base anchor is divided into an anchor part and a colloid part. The anchor part is composed of a screw, a lock key, a conical expansion head, a flat washer and a nut. The colloid part uses Nanjing Mankate’s MT500 planting bar glue. The colloid of this MT500 planting bar glue is a modified epoxy resin formula, and the strong anchoring force reaches the pre-buried structure effect. It has high temperature resistance, humid and heat resistance and the aging is up to 50 years.

What is the working principle of the adhesive mold expanded-base anchor?

The adhesive mold expanded-base anchor uses the reaming wall of the bottom of the hole and the lock key to form lock key effects and at the same time cooperates with the planting bar glue to complete the anchoring. Adhesive mold expanded-base anchors not only have the advantages of mechanical anchors, but also combine the shock resistance and impact resistance of the planting bar glue. It has high carrying capacity.

What is the installation procedure for the adhesive mold expanded-base anchor?

Here is an example model specification: M12*16*80-140 adhesive mold expanded-base anchor

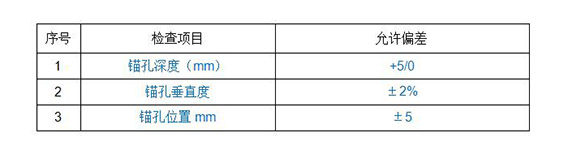

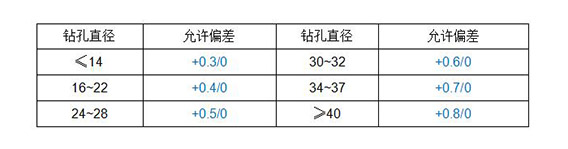

1. Drilling: A drill with a diameter of 16 is mounted on an ordinary impact drill. The drill handle is selected according to the type of the hammer to select four pits or five pits. When drilling, please determine the drilling depth to 100m (0-5mm); verticality, buried hole diameter, maximum clearance, etc. according to the specification JGJ/145-2013, as shown in the following table:

(the anchor hole depth of M12 adhesive mold expanded-base anchor)

(the drilling diameter of M12 adhesive mold expanded-base anchor)

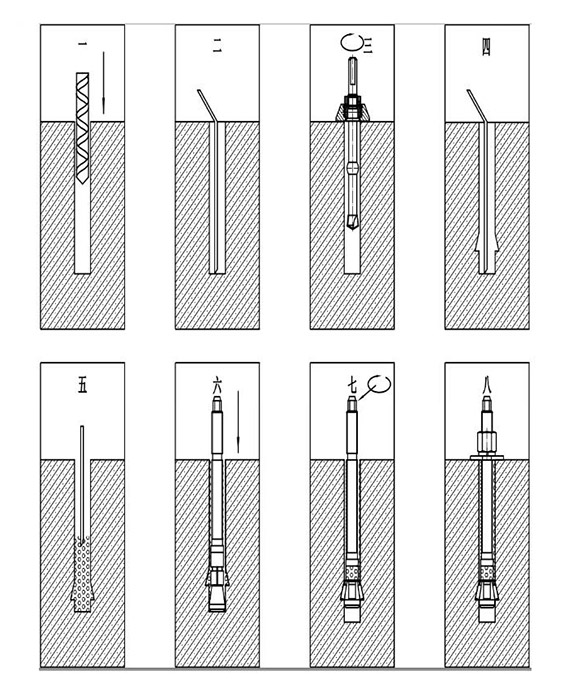

2, clear the hole: use a pneumatic pump to clear the hole, and the hole must be cleaned;

3. secondary reaming: secondary reaming with a special reaming tool;

4, secondary clearing: use a pneumatic pump to clear the hole, and the hole must be cleaned;

5, injecting the glue: the injection nozzle (mixer) is installed on the plastic bottle; check the injection nozzle that must have a spiral tube or discard; it is strictly prohibited to unplug the spiral tube in the injection nozzle; the plastic bottle is equipped with a special glue gun. The glue is squeezed at a constant speed. The glue of the first three shots should be discarded. The glue injection nozzle is inserted into the bottom of the hole, and the glue is slowly added to the outside. The normal injection amount is 2/3 of the hole volume. After the replacement of the new plastic bottle injection nozzle should also be replaced with a new; Remove the unfinished glue away from the glue nozzle and clean the glue outlet; the nut can be tightened again next time;

6. Installation: Before installation, first tighten the components of the anchor bolt and ensure that the components of the anchor bolt are not loose, and the lock button is also unopened, then use a hammer with a special tool (installation tool) to strike, push the anchor bolt into In the hole until the limit mark is flush with the plane of the concrete substrate;

7. Tighten the lock key effect: Apply torque to the top hex head with a torque wrench to 35N.M (torque wrench selects the range torque 0-100N.M), wait for the complete curing, and test the anchor design value with the puller; after the design value is reached, the subsequent construction is carried out; (5000 sets of test, 6 sets/group, less than 5000 sets are calculated according to 5000 sets)

8. Install the buried plate: Wait for the anchoring agent to solidify, install the buried plate and other anchors.

(Installation steps of M12 adhesive mold expanded-base anchor)

What are the uses of the adhesive mold expanded-base anchor?

1. Installation and fixing of equipment in industrial plants, conveying systems and lifting systems.

2. Connection and fixing of various curtain wall structures and steel structures.

3. Installation and fixing of various pipes for civil buildings.

4. All kinds of pipes of railways, tunnels and bridges, and the installation of cable supports.

5. Installation of various security doors, fire doors and security windows.

6. Suitable for high security requirements of concrete anchoring, anti-vibration and impact loads.

Editor: Nanjing Mankate, if you need to reprint, please indicate the source!

Original link: https://www.njmkt.net/Article/jzmkdmsxxd.html