1. Substrate treatment, grinding the concrete base with electric tools, grinding out the convex hull and the sharp corner of the stone.

2. Repair the base pits, scrape the concave surface of the concrete surface with the mixed leveling glue batch so that the base surface of the pasting area can reach a smooth condition, so as to facilitate the subsequent bonding of carbon fiber cloth ( don’t use concrete to repair; secondary structure has no connection strength, affecting the patch effect).

3. Apply the carbon fiber impregnated glue for the first time, apply glue (plate bottom) in the marked paste area, and use the paint roller to brush the W-shaped track to prevent dripping and save glue (avoid appearing the following situation).

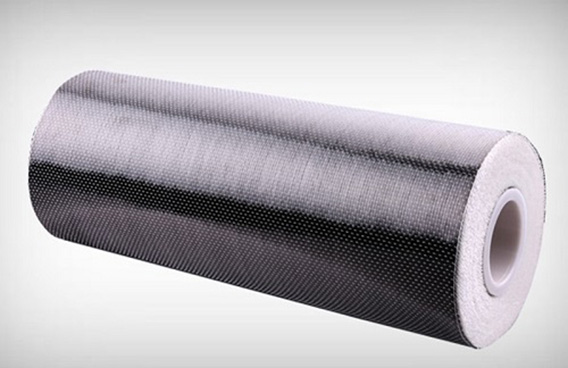

4. Paste the cut carbon fiber cloth onto the substrate, and use a plastic scraper to flatten the carbon fiber cloth in one direction so that the cloth is applied to the substrate surface.

5. Smear the carbon fiber impregnating rubber for the second time, apply the glue again on the surface of the carbon fiber cloth, scrape the carbon fiber cloth in one direction with a plastic scraper, remove the bubbles inside the carbon fiber cloth, so that the cloth is saturated with the glue, and the excess glue is scraped. Do not hang on the bottom of the board or on the beam.

6. Within 1~2 hours after the entire pasting area is pasted, spread the coarse sand evenly in the pasting area to facilitate subsequent application of the mortar.

Editor: Nanjing Mankate, if you need to reprint, please indicate the source!

Original link: https://www.njmkt.net/Article/zttxwbjgbd.html